| |

www.PrecisionStraightEdge.com

|

|

Special Precision Straight Edges |

|

|

| |

|

|

|

| |

Custom Designed Straight Edges

are Available |

| |

|

|

|

|

|

We also manufacture a complete line of steel standard straight edges with

lengths from 36" to 180". Most customers start with one of our standard steel units and make a few modifications.

We can easily add a second edge, change the thickness, bevel the edge, or drill mounting holes for a small extra

charge. The hot rolled steel is easy to work with and makes a very stable straight edge. Tool steel is not available

for lengths longer than 144-inches and there are very few heat treat facilities that can handle longer lengths.

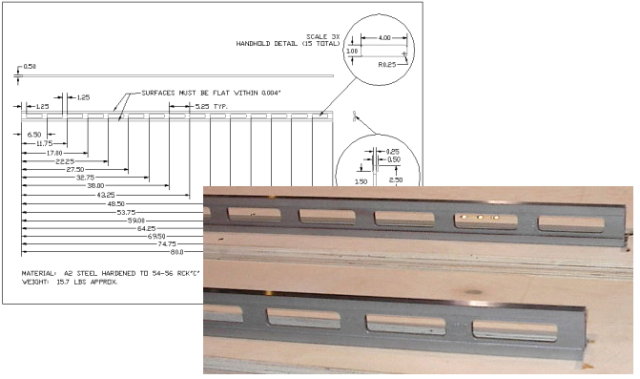

We can build special straight edges to your specifications. Our customers have already ordered specials that measure

from 15 inches (381 mm) to 16 feet (4,877 mm) in length. Please take a look at the sample prints for some of the

special designs we shipped. We offer many options that require choices for the design of a special straight edge.

Please call us at (937) 438-8031 if you have any questions about designing your straight edge. We can usually

find a low cost design together that will work for your application.

All of these details and choices can be confusing, so at some point in this process you can expect a CAD drawing

of the proposed straight edge to make sure we both understand what you expect. Then after we received your order

and upon your final approval of the design, we will start building your special straight edge. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

| |

CAD Drawings Utilized |

| |

|

| |

|

|

|

| |

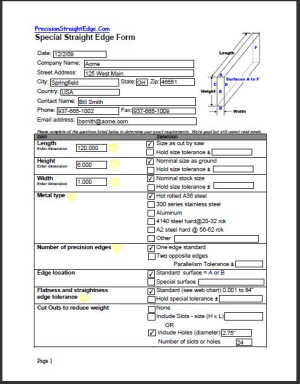

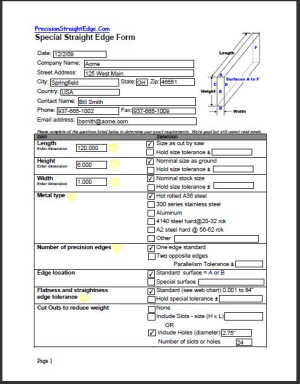

Designing Your Straight Edge Requires Information |

| |

|

|

|

| |

To design a special straight edge someone needs to make choices for each of the following selections before the

unit can be quoted. We already know our preferences but now we need your input to find out what meets your expectations.

We have designed a PDF form or give us a call at 937-438-8031.

|

| |

|

|

|

| |

|

- Contact Information?

- Dimensions?

- Metal Type?

- Number of Precision Edges?

- Edge Location?

- Flatness & Straightness Tolerance?

- Cut Outs to Reduce Weight?

- Channels Cut to Reduce Weight?

- Holes for Mounting Unit?

- Bevel on one Edge?

- Finish on Non-Certified Edges?

- Chamfer Corner?

- Serial Number Placement?

- How will Edge be Used?

- Inspection Procedures?

- Documentation Required?

- Packaging Required?

|

| |

|

|

|

| |

|

Or if you really hate forms, just send us an email or call 937-438-8031

|

| |

|

|

|

| |

|

| |

|

|

|

| |

| Dimensional Data - Design

Factors |

|

| |

|

|

|

| |

The cost of special straightedges is based on your specification from the above selections. We can even make special

units from just about almost any type of hardened steel that you might specify but prefer to work with the steels

listed above. Heat treating some exotic types of steels is challenging and very expensive for longer straight edges.

Heat treated straight edges frequently require an additional straightening and a stress relieving prior to precision

grinding.

We do make straightedges from non-magnetic materials such as stainless steel, aluminum, and ceramics, but the cost

these units cost more because the material is expensive and they are more difficult to grind. The soft edges on

Aluminum straight edges are much easier to nick or scratch than edges on steel units. |

| |

|

|

|

| |

Most of our smaller straight edges are 3-inches high to increase rigidity. Units longer than 8-feet long are at

least 4-inches high and our 14-foot long unit is 5-inches high. We typically drill large 2-3/8 inch diameter holes

in these straight edges that are over 8-feet long to reduce the total weight of the unit. Standard straight edges

up to 14-foot long are 1/2 inch wide to reduce bowing and bending, but they are not designed for unsupported loads

in this axis. The 1/2 inch width allows the unit to safely stand on edge without falling over. We can also manufacture

thinner units, but you may find that they may feel flimsy.

If your application requires a narrow edge, you could specify a beveled edge. Of course we can also make both thicker

and wider units for an additional cost, but the increased weight can be a problem with longer straight edges. The

weight for a steel design can be calculated by the following formulas: |

| |

|

|

|

| |

- Steel Unit Weight (in pounds)

= Length (inches) x Width (inches) x Thickness (inches) x 0.283

|

| |

- Aluminun Unit Weight (in pounds)

= Length (inches) x Width (inches) x Thickness (inches) x 0.094

|

| |

|

|

|

| |

While we closely hold the flatness and straightness for usually ONE edge, the height dimensional tolerances is

usually considered a nominal size that are subject to change after grinding. The length tolerance is usually held

only to the dimension as sawed and the width is usually the nominal dimension for the stock thickness. |

| |

|

|

|

| |

|

|

|

|

|

| |

![]()